The Glue Talk Blog

A Story about Labels

There’s a wide public debate about sustainability and the environmental impact of a fast-paced world where globalization, ready-to-go meals and e-commerce are real and booming. These are complex concepts, and everyone seems to have an opinion about it, but at the end of the day, we all seem to agree that packaging is changing towards eco-friendly options, either because the materials can be disposed without harming the environment or because they can be recycled and used again.

In a Confederation of European Paper Industries (CEPI) study, they found that more than 80 percent of European consumers prefer paper-based packaging. In fact, corrugated e-commerce packaging had the largest market share in 2017, according to a Smithers Pira report on e-commerce. But, how are these eco-friendly materials affecting the labeling industry?

Let’s look at two examples here: recycled corrugated packaging and coated cardboard. The first one has a very high share of recycled materials, 89 percent, to be more precise, according to FEFCO, as most corrugated material is recovered for recycling. Fibers of recycled corrugated boards are much shorter and packed together due to the nature of the recycling process, which makes it very different to work with compared to virgin corrugated boards. With single-use plastic being replaced by fiber-based materials, we also see more coated and treated cardboard surfaces, such as waxes to protect against humidity and fat, printing inks, and other coatings to achieve a glossy surface. While these applications are important to the packaging industry, these are usually hard-to-bond materials and may not be fully recycled.

As new is made out of old, label converters need to consider the different substrates that keep emerging in the packaging world and create solutions that meet versatility.

Why Are We Talking About Labels?

Labels play a number of roles on a package. Logistic labels, for example, are of the utmost importance as they act as a passport for products. Product names, specifications, origins and recipients are on the label. Nothing else is attached to the corrugated box with this information, so they are crucial for commercial transactions between sellers and buyers. Direct print to the corrugated box doesn’t offer excellent scannability so the logistic labels market is forecasted to grow.

While e-commerce growth asks for faster and longer-distance transportation, PSAs for logistics labels applied to rough surfaces, like cardboard, require a very reliable adhesion to prevent the label from peeling off during transport. Withstanding different climate zones and maintaining its integrity is crucial for labels. In a scenario where boxes are packed tightly into containers, even the slightest peel-off in the corner of a label may cause the label to be misplaced, and the content of that package to lose its value.

Do You Have the Right Product?

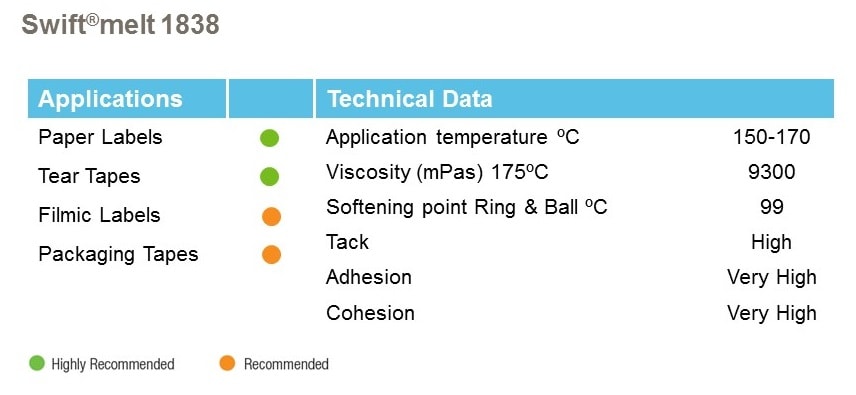

Swift®melt 1838 has been designed by H.B. Fuller scientists for the Tapes and Labels market. The advantage of this adhesive is that it delivers strong adhesion to a range of substrates, including both polar and unpolar materials. For the rough cardboard surfaces I mentioned earlier, its good adhesion would cause fiber tear of the cardboard surface, which is ideal for logistics labels. This product also may be used for tearing tapes for an easy opening of cardboard boxes.

Do You Have the Right Supplier?

Pressure-sensitive adhesive for labels needs to be fully tested when a new substrate is introduced so both packaging manufacturers as label converters need to work together as they transform businesses to accommodate new and more sustainable materials. And, they also need to work closely with their own suppliers. They need to partner with a strong R&D and technical support provider.

At H.B. Fuller, we have what it takes to bring you to the next level. We can help you stay ahead of changes in production, help you go linerless, and even test our Swift®melt 1838 with the thermopaper used at your production site. Come see us at Labelexpo in Brussels. We’ll be ready to answer your questions at booth D43 in hall 11 from the 24th to the 27th of September. Bring us a challenge and we’ll be happy to work on a solution with you!

Blog Categories

Blog Categories

Archive

- 2024

- 2023

- 2022

-

2021

- January (3)

-

February (7)

- Celebrating Exceptional Service During COVID-19 Complications

- Cyanoacrylates: What They Are and What They Do

- Innovative two-shot bookbinding adhesive

- Make a Difference 2020

- Problem Solving: Paper Straws in Drinking Beverages

- Stronger straws sustainable future

- Substances of Interest in Disposable Absorbent Hygiene Products

- March (4)

- April (4)

- May (4)

- June (5)

- July (2)

- August (5)

- September (2)

- October (1)

- November (3)

- December (2)

-

2020

- January (4)

- February (2)

- March (3)

- April (4)

- May (3)

-

June (7)

- Community Support in the Era of Coronavirus

- HBFuller Employee Creates Face Shields with 3D Printer

- Improved Packaging Integrity and Greater Customer Satisfaction

- Liquid-Resistant Paper Straws

- What is a Sealant?

- What Is the Future of Commercial Disinfectants?

- Winning over consumers with e-commerce packaging solutions

-

July (6)

- Employees Take Action to be Part of Healing and Growth

- Gain a competitive advantage with packaging adhesive solutions

- HB Fuller Company Foundations Commitment to Communities

- Packaging Solutions for the South African Agriculture Market

- Supporting Organizations That Provide STEM Education for Youth

- Where Does Sustainability Stand Amid COVID-19

- August (3)

- September (2)

- October (4)

- November (2)

- December (4)